Products

-

The LMX

Lab Mixer -

The VHS

High-Speed Disperser -

QUICK SHIP

High-Speed Disperser -

The VLS

Low-Speed Mixer -

MULTI-SHAFT

Mixers & Dispersers -

TANK-MOUNT

Mixers & Dispersers -

The ILD

Inline Disperser -

The VDM

Vacuum Drum Mixer -

The VRS

Rotor Stator -

The EMI

Lab Mill -

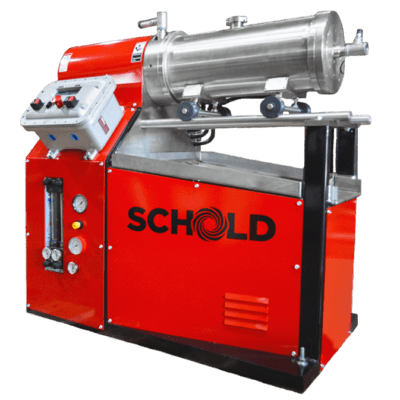

The HSM

Horizontal Media Mill -

The VSM

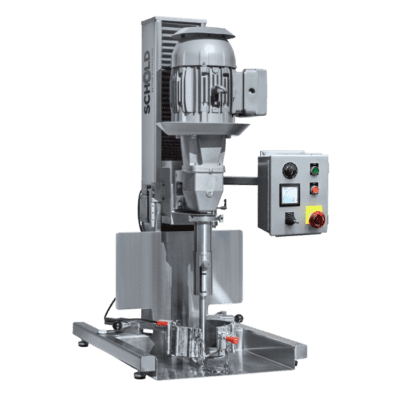

Vertical Media Mill -

The VIM

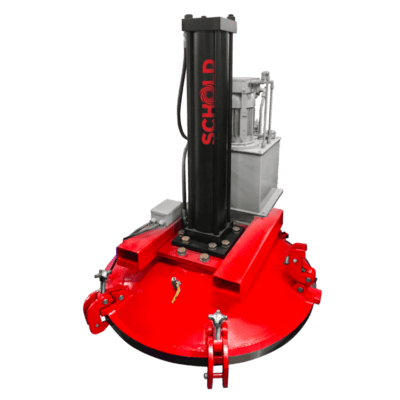

Immersion Mill -

DISCHARGE PRESS

Stationary -

DISCHARGE PRESS

Portable -

BLADES

for Mixing & Dispersing