Who is Schold?

History

In 1949, Schold was founded in Chicago by George Schold, who had a vision to provide high-quality industrial dispersers, mixers, and mills for customers around the world – a vision that was realized.

Since that time, Schold has manufactured 15,000 machines, served 1,700 customers and supported 90+ different industries, all while remaining a client-centric solutions provider.

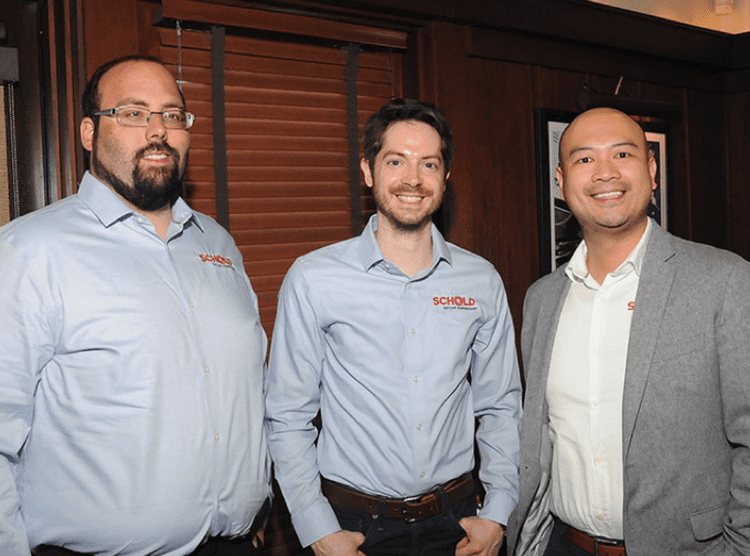

Under the new ownership of Chris Spatz, John Duong and Mike Barr since 2016, Schold has been able to blend old-school wisdom with new technology to create a promising future for employees and customers alike.

History

In 1949, Schold was founded in Chicago by George Schold, who had a vision to provide high-quality dispersion equipment for customers around the world – a vision that was realized.

Since that time, Schold has manufactured 15,000 machines, served 1,700 customers and supported 90+ different industries, all while remaining a client-centric solutions provider.

Under the new ownership of Chris Spatz, John Duong and Mike Barr since 2016, Schold has been able to blend old-school wisdom with new technology to create a promising future for employees and customers alike.

QUALITY

SERVICE

COLLABORATION

INNOVATION

QUALITY

SERVICE

COLLABORATION

INNOVATION

74

14,941

1,743

90+

SCHOLD TEAM

Principal Engineer

Business Development

Parts & Service Manager

President

Executive Administrator

Sales Engineer

Key Accounts Manager

Automation Engineer

Mechanical Engineer

Plant Manager

Sales & Marketing

Mechanical Engineer

Office Administrator

Mechanical Engineer

Vice President of Sales

Mechanical Engineer

Systems Engineer

Mechanical Engineer

TRUSTED COMPANIES USING SCHOLD EQUIPMENT: